Table of Contents

I.Industry Status

The coated abrasives industry in Australia has shown steady growth in recent years,driven by the recovery of domestic manufacturing and sustained demand in sectors such as construction and automotive.While the market size is not as large as that of the United States or Europe,Australia's industry holds a significant position in the Oceania market due to steady local manufacturing growth and a strong emphasis on high-quality products.

Key coated abrasive products include abrasive belts,sandpaper,abrasive rolls,and discs,which are widely used in metalworking,woodworking,automotive repair,construction,and home improvement.The Australian market is characterized by a strong focus on quality,with customers preferring locally manufactured products or internationally certified brands.

II.Major Product Categories and Application Fields

Product Categories

1.Abrasive Belts:

Used for polishing and deburring metals and wood,suitable for industrial production lines and manual finishing.

2.Sandpaper and Abrasive Rolls:

Commonly employed in building decoration,wood polishing,and automotive repair.

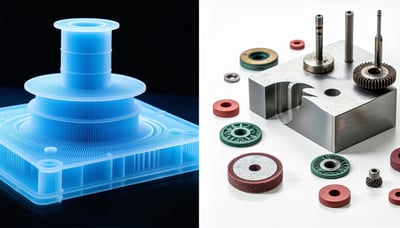

3.Abrasive Discs and Fiber Discs:

Primarily used for metal surface treatment and weld grinding,often supplied by local companies in collaboration with international brands.

Application Fields

1.Metalworking:

The metal manufacturing and repair industry represents the largest market for coated abrasives,involving cutting,polishing,and deburring of metal components.

2.Woodworking:

Coated abrasives are used for furniture manufacturing and wood surface treatment,with construction and furniture companies being the primary customers.

3.Automotive Repair:

High-quality sandpaper and polishing tools are essential for car body repair and painting.Companies specializing in automotive repair and painting have a strong demand for premium coated abrasives.

III.Local Enterprises and Representative Brands

1.Abrasiflex

Founded in 1975 and headquartered in Perth,Abrasiflex has production facilities in Perth and Melbourne and warehouses and distribution centers in several major Australian cities.

Abrasiflex is one of Australia's leading manufacturers and suppliers of coated abrasives,specializing in abrasive belts,discs,and polishing products.It collaborates with multiple international brands.

As Australia's most well-known local coated abrasives brand,Abrasiflex provides a reliable supply for domestic manufacturing and construction industries,serving a wide range of customers from small workshops to large industrial enterprises.

2.Lynfurn Australia

Lynfurn focuses on the import and distribution of coated abrasives and is the official Australian distributor of the Portuguese brand INDASA.It handles the distribution of INDASA's Whiteline,Plusline,Redline,and Filmline series of coated abrasive products.

The company supplies coated abrasives such as sandpaper,abrasive belts,rolls,and discs,suitable for various applications,including automotive repair,wood polishing,and composite material processing.

As a representative of international brands,Lynfurn targets customers requiring high-quality coated abrasives.Its premium brand positioning has secured a market share,particularly in automotive repair and building decoration.

3.111 Abrasives Australia

Since its founding in September 1987 under the name Mullner Enterprises,111 Abrasives Australia Pty Ltd has provided innovative abrasive solutions and metalworking tools to the Australian market.

The company manufactures abrasive belts,flap wheels,and fiber wheels,widely used in metalworking,woodworking,and precision surface finishing.

With its technological innovations and high-performance products,111 Abrasives Australia has earned an excellent reputation among industrial customers,especially those in high-end manufacturing and automotive repair sectors.

4.Workmate Abrasives

Founded in 1993,Workmate Abrasives is a localized coated abrasives company that focuses on providing a wide range of coated abrasive products for metalworking,woodworking,and automotive repair industries.

Its product line includes abrasive belts,various standard and custom-sized abrasive discs,sandpaper,and abrasive rolls,all aimed at offering customers cost-effective and localized services.

As a local business,Workmate Abrasives holds a certain market share in the metalworking and woodworking sectors in Australia.Its flexible customization solutions and local supply chain provide efficient service to its customers.

Workmate Abrasives will be exhibiting at the 2025 Australian Hardware Tools Grinding Exhibition

Booth Numbers:B40 B03

5.Josco

Josco is an Australian company that specializes in surface preparation and hand tools.Established in 1977,it offers a variety of surface treatment and grinding products,including wire brushes,Strip-It abrasive discs,carbide milling cutters,flap discs,and flap wheels,among others.Josco also operates several sub-brands,including Brumby,Tomcat,and Josco Clean,some of which are well-known in Australia's hardware and home improvement markets.

In addition,international brands like 3M,Saint-Gobain,and PFERD hold significant market shares in the Australian market.

IV.Market Competitive Landscape

The Australian coated abrasives market features a competitive environment with both local and international brands coexisting.Local companies leverage advantages such as local production and rapid delivery capabilities to establish a strong customer base in the metalworking,construction,and woodworking markets.At the same time,international brands occupy a place in high-end markets through distribution channels,relying on premium products and global reputations.

V.Market Development Trends and Prospects

1.Growth in Electric Vehicle Demand:

The increasing demand for electric vehicles has driven a rise in the need for grinding and precision finishing of related metal components,thereby boosting the demand for coated abrasives.

2.Infrastructure Construction and Manufacturing Expansion:

The growth of construction and infrastructure projects has also stimulated the demand for abrasives,particularly in surface treatment and decoration processes for building materials.

3.Increasing Demand for High-End Customization:

As Australia's manufacturing industry becomes more intelligent and refined,the demand for high-end,customized coated abrasives products is on the rise.This is especially true for high-end grinding products used in automotive repair and composite materials.

4.Competitive Advantage of Local Manufacturing:

Due to Australia's geographical remoteness and relatively high logistics costs,local manufacturers have a competitive edge when responding to supply chain fluctuations,particularly excelling in fast deliveries and customized products.

5.Promotion of Environmentally Friendly Products:

As environmental regulations become more stringent,coated abrasive products made from sustainable materials are gaining popularity in the market.Many manufacturers are investing in the development of biodegradable sandpaper and environmentally friendly coating technologies to meet the growing demand for green products.

VI.Market Entry Strategy

Given that Australia's abrasives market has a high recognition for quality products,it is recommended that Chinese companies consider collaborating with local distributors or retailers to expand their market reach through existing local distribution networks.

Additionally,participating in industry trade shows such as the Australian Tools Grinding Exhibition(ATGE)can help enhance brand visibility and market penetration.