Hardness Uncovered: The Key Code to Materials, Tooling, and Machining Performance

Table of Contents

- What Is Hardness?

Hardness refers to a material’s ability to resist localized plastic deformation when subjected to mechanical force or friction—essentially, its resistance to indentation or scratching. The harder the material, the higher its strength usually is. However, increased hardness also tends to make the material more brittle, making it more prone to cracking under load. This property has a significant impact on material selection and affects mechanical performance, service life, and manufacturing costs.

In machining, understanding the hardness of the workpiece material is critical because it directly influences tool selection, carbide grade choice, and optimal cutting conditions. Today, the Abrasivestocks editorial team will give you an overview.

Rockwell Hardness (HRC/HRB/HRA)

Brinell Hardness (HB)

Vickers Hardness (HV)

- Units of Hardness Measurement

There are multiple methods and units for measuring hardness. In machining, the three most common are Rockwell, Brinell, and Vickers hardness.

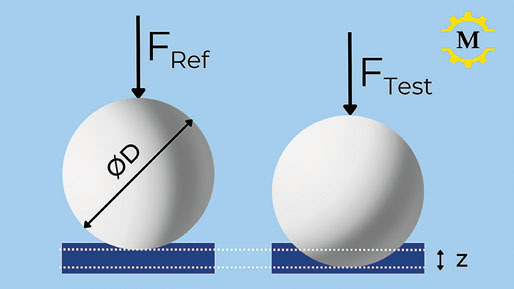

Rockwell Hardness (HRC/HRB/HRA):

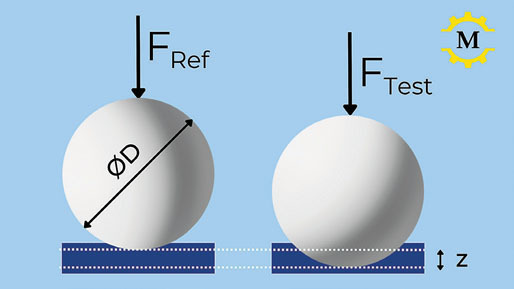

The most common unit found on engineering drawings. It measures the difference in penetration depth between a major load and a minor preload. There are nine scales (A to K) with different loads and indenter ball sizes.

HRC is the standard scale for metallic workpieces in machining, typically ranging from 10–65 HRC.

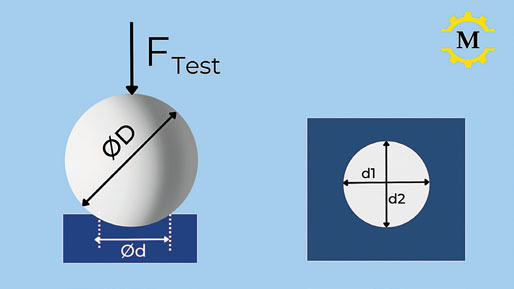

Brinell Hardness (HB):

Commonly used for measuring raw materials, such as in cutting condition tables in tooling catalogs. It uses a 10 mm steel ball under a load of 3,000 kgf (6,614 lbf). Metals generally range from 100 HB (soft) to 650 HB (hardened steel).

HRC is only applicable to materials harder than 180 HB, while softer metals use HRB. Brinell hardness can cover the entire hardness spectrum.

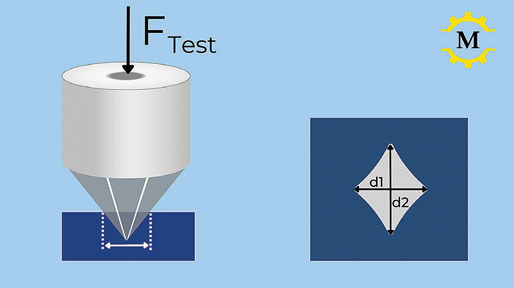

Vickers Hardness (HV):

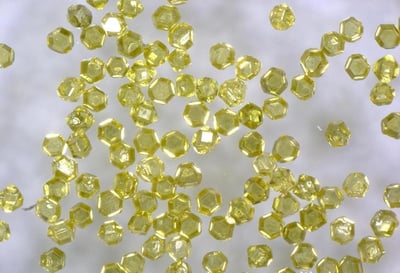

Frequently used to describe the hardness of tool materials such as carbide, ceramics, cubic boron nitride (CBN), and polycrystalline diamond (PCD). It uses a diamond pyramid indenter, and the HV value is the ratio of load to the surface area of the indentation.

Typical hardness ranges: carbide 1,300–1,900 HV, ceramics up to 2,000 HV, CBN about 3,000 HV, and PCD up to 6,000 HV.

- Hardness Conversion

There is no universal formula for converting between hardness scales—conversion is usually based on charts. Nowadays, online conversion tools are also widely used, allowing you to enter a value in one scale to obtain the corresponding value in others.

- Hardness and Machining

Hardness greatly influences machinability, including tool life, power consumption, and material removal rates.

Workpiece Material:

Very soft metals (below 180 HB) tend to cause built-up edge (BUE) formation on the cutting edge, making chip evacuation difficult. Very hard materials, on the other hand, accelerate tool wear and reduce cutting speeds and tool life.

A hardness of around 200 HB (about 15 HRC) is generally considered an optimal range for machining; harder materials require advanced tooling such as ceramics or CBN.

- Tool Materials

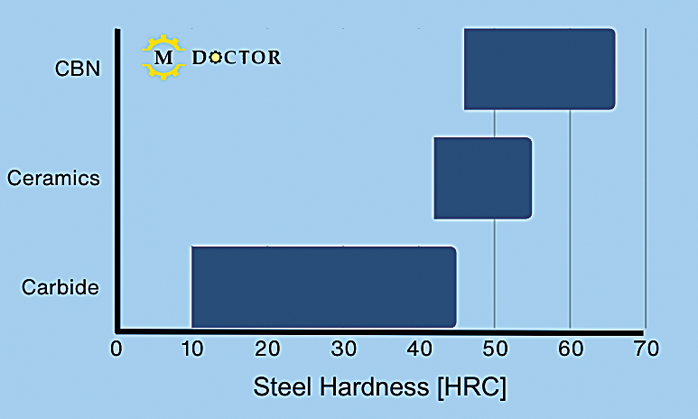

Carbide:

The primary base material for modern cutting tools, suitable for workpiece hardness from 12–45 HRC (180–450 HV). Carbide hardness ranges from 1,300–2,000 HV. Higher-hardness grades can handle more demanding machining but are less tough and more prone to chipping. Some carbides can reach 65 HRC (950 HV) after heat treatment, requiring more advanced tooling.

Ceramics:

Made from aluminum oxide (Al₂O₃) or silicon nitride (Si₃N₄), ceramics have a hardness of 2,100–2,500 HV—about 40% higher than carbide—and can machine steels up to 55 HRC.

CBN:

Polycrystalline cubic boron nitride has a hardness of about 4,500 HV and excellent thermal and chemical stability, making it suitable for machining steels up to 70 HRC and other hard-to-cut materials.

In Summary

Hardness is not only a key indicator of material performance but also a critical factor influencing machining processes, tool selection, and production efficiency. Whether for workpiece or tool materials, matching hardness appropriately with the machining method ensures both high-quality results and extended tool life—while reducing production costs and enabling more efficient, stable manufacturing.