Table of Contents

Ceramic cutting tools, known for their excellent heat resistance and high-speed machining capabilities, are increasingly being adopted in metal cutting applications. However, limited industry awareness has prevented many machining enterprises from fully realizing the potential of ceramics, or recognizing their feasibility and cost-effectiveness in replacing traditional tool materials in specific scenarios.

1. Core Advantages of Ceramic Tools

Ceramic materials offer outstanding thermal conductivity during cutting, efficiently dissipating the heat generated in the cutting zone away from the cutting edge. This reduces thermal wear and extends tool life. In contrast, conventional materials such as cemented carbide, cubic boron nitride (CBN), and polycrystalline diamond (PCD) have lower thermal conductivity, leading to heat accumulation near the cutting edge and accelerated wear.

Thanks to their thermal performance, ceramic tools can operate at significantly higher cutting speeds. For instance, when machining heat-resistant alloys, typical cemented carbide tools operate at about 125 SFM (surface feet per minute), while ceramic tools can reach speeds of 800 to 1500 SFM. Some advanced ceramic materials can even achieve up to 1600 SFM. This high-speed capability greatly improves material removal rates and overall productivity.

2. Limitations of Ceramic Tools

Despite their speed advantage, ceramic tools also have certain limitations. Due to the inherently brittle nature of ceramics, achieving a sharp cutting edge is more difficult compared to cemented carbide. This results in a lower edge sharpness and sometimes reduced performance in specific applications.

Manufacturing costs are another concern. For example, indexable ceramic inserts require extensive precision grinding after forming, making mass production more difficult and costly compared to conventional materials. Depending on shape and size, ceramic inserts can cost 1.5 to 4 times more than standard inserts, while solid ceramic tools may cost 2 to 4 times as much.

Moreover, high-speed operation requires higher-performance equipment. Although many manufacturers show interest in ceramic tools, inadequate spindle speeds or lack of appropriate tool parameter knowledge often prevent the tools from reaching their full performance potential.

3. Typical Application Areas

Ceramic tools are particularly well-suited for high-temperature, high-hardness, and difficult-to-machine materials, including but not limited to the following:

- High-Hardness Stainless Steel

Ceramic tools perform well when machining stainless steels with Rockwell hardness above 32–35. Under these conditions, cutting temperatures are extremely high, allowing ceramics to demonstrate their thermal stability and high-speed capabilities. For lower hardness materials, excessive heat can cause surface melting or even combustion. - Powder Metallurgy Materials

Common in automotive components, powder metallurgy parts present both abrasive and thermal challenges that rapidly wear down tools. While CBN tools are often used, their cost is very high. Ceramic tools offer good performance at significantly lower cost. - Compacted Graphite Iron (CGI)

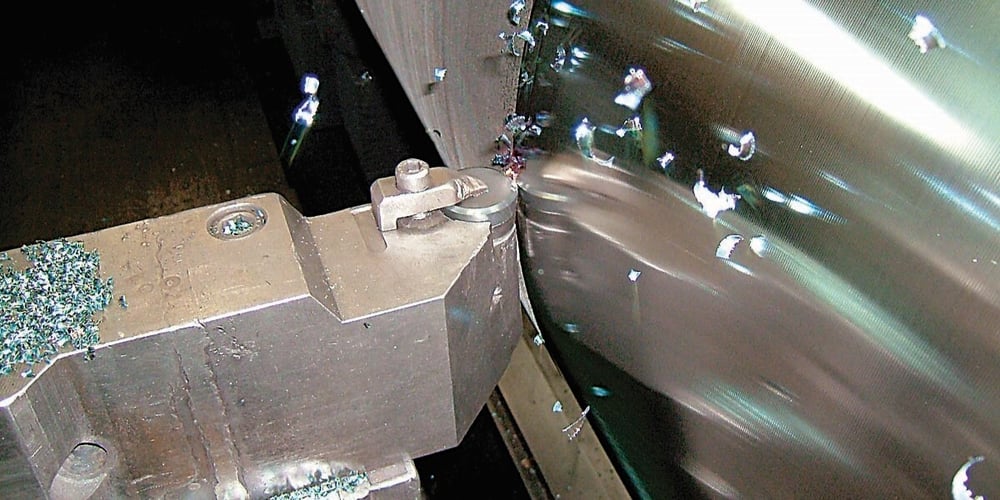

CGI is a high-strength iron material widely used in diesel engine blocks. It causes rapid wear on traditional tools. Ceramic tools offer excellent cost-effectiveness in this application, with tool life exceeding that of carbide tools by more than 10 times. - Grinding Process Substitution

In the machining of high-hardness components, ceramic tools can replace external or surface grinding operations, significantly improving material removal rates and reducing total machining time. Unlike grinding wheels, ceramic tools also allow for flexible toolpath control via CNC programming. - EDM Process Substitution

In certain moldmaking or hardened part applications, solid ceramic end mills can replace roughing stages of EDM (Electrical Discharge Machining), rapidly removing material and reducing the number of electrodes needed, along with the time required to manufacture them.

4. Advances in Materials and Manufacturing

Recent developments in ceramic tool materials and manufacturing processes have significantly improved their mechanical properties and broadened their machining suitability. Examples include:

- Whisker-Reinforced Ceramics: Incorporating whisker-like reinforcement phases grown within the ceramic matrix greatly enhances fracture toughness and impact resistance, enabling their use in roughing and interrupted cutting.

- Composite Ceramic Structures: New materials combine ceramic and carbide in an interwoven network structure. This design takes advantage of ceramic thermal conductivity and carbide heat transfer paths, improving thermal diffusion and tool life without the need for cobalt binders. Such materials have been successfully applied to aerospace engine components, achieving cutting speeds up to twice that of conventional ceramics.

Conclusion

Advancements in ceramic cutting tool technologies have made them highly competitive in areas such as high-temperature alloys, powder metallurgy, CGI, and certain traditional grinding operations. Although challenges remain—such as high costs, narrow process windows, and geometric limitations—their benefits in speed, cycle time reduction, and tool longevity are significant. With continuous improvements in machine tool capabilities and greater user familiarity, ceramic cutting tools are expected to find broader application across various industries.